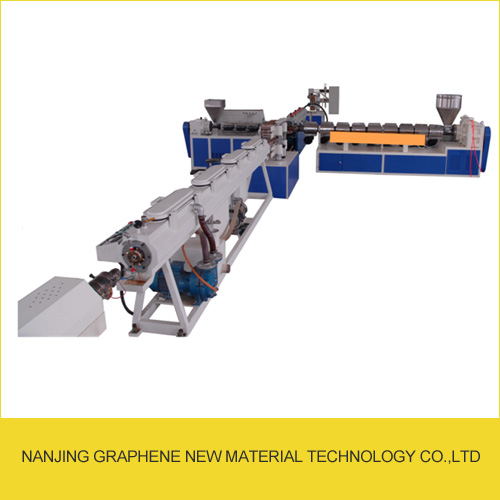

Physical PE foam pipe production line was designed by NANJING GRAPHENE NEW MATERIAL TECHNOLOGY CO.,LTD,It has reached the international advanced level, the equipment is initiative in the domestic to make inner pipe, PE foam layer and sheath layer one time forming, and achieve continuous uninterrupted production condition, at the same time is also available in copper, aluminum, steel and other materials of the composite pipe.

The basic parameters:

1、 model number: HD – 75

2、 the total power: 90 kw

3、 foaming degree: 75-87%

4、 extrusion output: 8000 meters/day

5、 pipe diameter range: Φ8 – Φ 50 mm

The tractor has two claws, three claws, four claws, six claws, eight claws and other traction modes. It can choose saw blade cutting type or planetary cutting type, with length meter and thickening device, the unit has reliable performance and high production efficiency. The company can produce inner wall spiral pipe, inner wall hollow pipe and core layer foam pipe unit replacement extruder after equipped with special device according to the user’s requirements, and can produce PP, PE, ABS, PPR, PEX, silicon core pipe and other material pipes. Planetary cutting machine adopts full-automatic computer numerical control, which has the advantages of convenient operation, reliable performance, etc., reaching the international level.

Performance characteristics:

◆ Through the foaming to control and change the products materials physical state, achieve qualitative light, heat preservation, environmental protection;

◆ The whole line realize the inner tube manufacturing, foaming, film coating, cooling and winding process. Stability and controllability are strong.

◆ Using temperature control module, PLC and touch-screen integration, compared with the conventional extruder, has high degree of automation, reduce the labor intensity, reduce the cost.